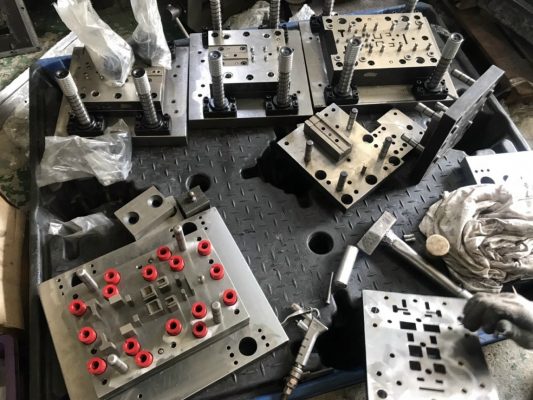

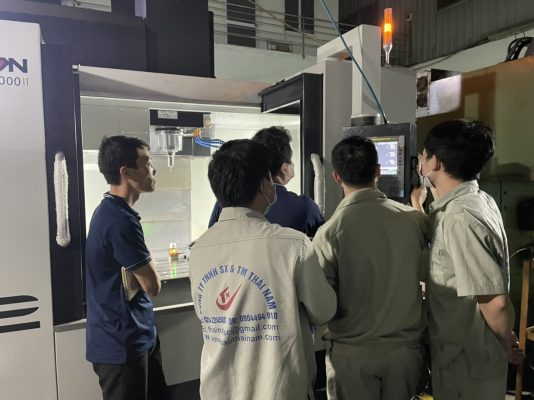

Last week, I had a visiting at the factory of Thai Nam Production and Trading Company in Lai Xa Industrial Cluster (20km far from Hanoi City center, Vietnam). Their CEO/Founder, Mr. Nguyen Van Hoi welcomed me and showed their products and assembly lines. Thai Nam has had 10 year-experience in producing metal components, assembly jigs, molds, mechanical items, and etc.

The CEO told me that at the moment, they are preparing to enlarge their factory and export directly to global market. For many years, they have supplied items to domestic customers or international customer through middleman partners. They have invested a lot of efforts, equipment and skilled labors to meet customer demands of quality and delivery time.

As we can see, the China’s zero-COVID-19 policy has had impacts on global supply chains. Vietnam has been gradually chosen as one of new candidates in the supply chain. In fact, recently, during my work as a market development expert, many enterprises have informed me that they have received more and more orders of OEM components from international customers from US, Germany, Korea, Japan and etc.

According to the Vietnam Association of Mechanical Enterprises (VAMI), over 500 Vietnamese enterprises provide metal parts, components and assemblies. These enterprises have produced molds of all kinds, mechanical components, electrical cables, plastic components, technical rubber…The industry of manufacturing metal components for agricultural machinery, movers and construction machines is also relatively developed with a relatively high localization rate.

If your primary products or raw materials are coming from a single source, this creates serious risk. Preparation of some potential alternate suppliers are important to maintain your continuous production. Think about it and prepare for the unexpected before it is too late!

“There is only one thing in life which never changes, and it is the change.” – Confucius